Materials that perform.

Service that delivers.

Partnerships that last.

Who We Are

Orion Performance Compounds is a custom compounder specializing in engineered thermoplastics with advanced color, performance, and regulatory requirements. Founded in early 2023, Orion was created to fill a growing gap in the industry—the need for a compounding partner that combines technical depth, speed, and flexibility with modern manufacturing capabilities and a highly collaborative approach.

Our team brings decades of formulation, application, and manufacturing expertise, enabling us to support complex customer needs across a broad range of industries, including:

- Healthcare

- Electrical & Electronics

- Industrial Equipment & Components

- Consumer Products

Why Orion Was Founded

Orion Performance Compounds was launched in response to a changing and challenging landscape in the plastics compounding industry.

Years of industry consolidation, much of it led by private equity, reduced the number of independent compounders and shifted priorities toward scale and margin over service and flexibility. As competition decreased, many customers began to feel the effects:

- Rising prices

- Longer lead times

- Inconsistent quality

- Limited technical support

- A shrinking focus on niche or mid-volume markets

This shift created a real need for a new kind of partner—one focused on customer experience, technical excellence, and market responsiveness. Orion Performance Compounds was founded to meet that need.

Our goal is to restore what made compounding valuable in the first place: the ability to listen, customize, collaborate, and deliver. We’re built to support not just high-volume programs, but also the small- to mid-size opportunities and specialized applications that larger, consolidated players have moved away from.

From day one, our mission was clear:

- Build a technically capable, agile, and customer-focused organization

- Deliver high-performance materials with speed and precision

- Invest in modern equipment, best practices, and scalable infrastructure

- Make it easy for customers to work with us (no red tape, no slowdowns)

Why We Chose Lugoff, South Carolina

Orion headquarters are in Lugoff, South Carolina, just 20 miles outside of Columbia. With excellent access to major transportation routes and fast-growing industrial markets across the Southeast, we are strategically located:

- 300 yards from I-20

- 15 minutes from I-77

- 30 minutes from I-95

- 40 minutes from Columbia Metropolitan Airport (CAE)

- 90 minutes from Charlotte Douglas International Airport (CLT)

- 120 minutes from the Port of Charleston

- 165 minutes from the Port of Savannah

This location places Orion within 1–2 days transit of nearly two-thirds of all plastic molding operations in the United States, enabling efficient shipping and fast service to customers across multiple regions. South Carolina continues to be one of the nation’s most business-friendly and fastest-growing states, offering a strong industrial base, access to experienced labor, and a supportive regulatory environment.

Our site spans 27 acres and includes a 50,000 sq. ft. manufacturing facility that was purpose-built for expansion. The current footprint includes space for multiple additional production lines, and the land is pre-graded for a 50,000 sq. ft. expansion, allowing us to more than double production capacity as demand grows.

Infrastructure was designed to scale, with systems such as:

- Electrical capacity

- Plumbing and air handling

- Dust and fume collection

- Chilled water and compressed air systems

All these systems were installed with the intent of supporting a facility twice the current size with four times the current number of production lines, minimizing future disruption and ensuring readiness for sustained growth.

This strategic location keeps Orion connected, scalable, and customer-focused—now and into the future.

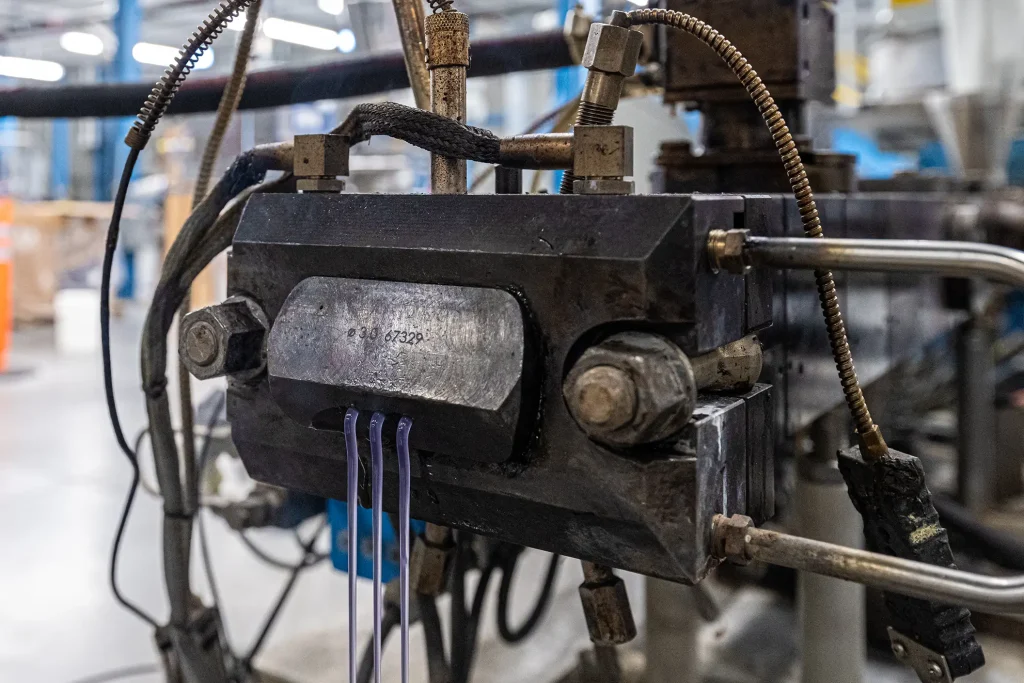

Equipment

Our facility proudly runs four state-of-the-art extruders, featuring a combination of twin-screw and single-screw systems to meet the diverse needs of our clients.

We invest in only the best. Our machines are top-of-the-line, sourced from renowned German-engineered brands known for their precision, reliability, and innovation. With a commitment to quality and efficiency, our extrusion lines are built to handle demanding applications with consistency and control.

Whether you’re looking for custom processing capabilities or scalable production support, we bring the right mix of expertise and equipment to deliver exceptional results, every time.

Products

Orion develops and manufactures custom thermoplastic compounds designed to meet the mechanical, aesthetic, and regulatory needs of demanding applications.

We formulate across a broad range of base polymers, including:

- Olefins: PE, PP, POK

- Polyamides: PA6, PA66, PA6/10, PA6/12, PA12

- Polyesters & Styrenics: PBT, PET, ASA, ABS

- Blends: PC, PC/ABS, PC/PBT

- High-Performance Resins: PPA, PPS, PSU, PPSU, PEEK

- Thermoplastic Elastomers (TPEs): TPO, TPS, TPV, TPA, TPU, TPC

- Additional resins available upon request

We specialize in application-specific compounds, including:

Aesthetic & Regulatory Compounds

Orion develops and manufactures custom thermoplastic compounds designed to meet the mechanical, aesthetic, and regulatory needs of demanding applications.

We formulate across a broad range of base polymers, including:

- Olefins: PE, PP, POK

- Polyamides: PA6, PA66, PA6/10, PA6/12, PA12

- Polyesters & Styrenics: PBT, PET, ASA, ABS

- Blends: PC, PC/ABS, PC/PBT

- High-Performance Resins: PPA, PPS, PSU, PPSU, PEEK

- Thermoplastic Elastomers (TPEs): TPO, TPS, TPV, TPA, TPU, TPC

- Additional resins available upon request

Performance Compounds

- Glass- and mineral-filled compounds

- Fiber-reinforced systems (e-glass, s-glass, carbon fiber)

- High specific gravity compounds (tungsten, copper, and other metal fillers)

- Lubricated compounds (PTFE, silicone, molybdenum disulfide, etc.)

- Electrostatic-dissipative and conductive materials (carbon fiber, carbon powder, stainless steel powder, graphite, and others)

- Antimicrobial compounds for consumer, healthcare, and high-touch applications

- Impact-, UV-, and flame-retardant grades

Services

Beyond manufacturing, Orion offers a suite of technical and customer support services designed to accelerate development and improve outcomes.

Our services include:

- Color Matching & Development: Fast, accurate matching across multiple resin families, even in filled systems

- Custom Formulation: Application-driven material design based on specific performance and processing needs

- Technical Support: Hands-on engagement from our experienced team to troubleshoot, optimize, or innovate

- R&D Collaboration: Joint development projects, early-stage prototyping, and material innovation

- Flexible Order Quantities: Small MOQs for trials and development; scalable solutions for production

- Responsive Lead Times: Standard turnaround of five weeks, with expedited options available

We operate with the agility of a startup and the depth of a technical partner, helping customers move from concept to production efficiently.

Lab & Quality

Our in-house laboratory is built to support both development and production with a full range of analytical, color, and mechanical testing capabilities. Lab features include:

- Color Matching & QC Validation (spectrophotometry, visual evaluation)

- Melt Flow & Rheology Testing

- Mechanical Property Testing (tensile, flexural, impact)

- Thermal Analysis (DSC, TGA)

- Moisture Analysis

- Density, Hardness, and Ash Content

- Environmental and UV Stability Testing (available through partners)

- Regulatory (UL Flame Booth)

We operate under a certified ISO 9001:2015 Quality Management System, ensuring consistent processes, traceability, and continuous improvement across our organization.

Our quality control process ensures that each lot meets exact customer specifications and maintains consistency from batch to batch. Every order is tracked, tested, and documented, providing confidence in performance and compliance.

Certifications & Regulatory Support

Orion compounds are developed with compliance and certification in mind for highly regulated industries such as healthcare, electrical, and consumer products.

Key certifications and regulatory support include:

- ISO 9001:2015 certification for our quality management system

- UL Yellow Cards for a growing list of recognized compounds

- Healthcare formulations with biocompatibility and regulatory traceability

- RoHS, REACH, and Proposition 65 compliance support

- Material certification and lot traceability upon request

- Ongoing investment in testing and documentation systems to support customer requirements

We work closely with our customers to ensure that material compliance, documentation, and testing are never obstacles to success—whether you’re preparing for FDA review, OEM approval, or third-party testing.